How it works

By using N2, water used in the fracturing fluid can be significantly reduced.

Reducing the liquid volume needed to complete the fracturing treatment provides economic and environmental benefits.

Using nitrogen with water or oil-based fluids can alter the physical properties of the base fluid, including reducing the viscosity, minimizing relative permeability effects and lowering surface tension.

The dissolved N2 breaks out of solution during drawdown ensuring a gas phase exists in the pore space and energized flow is achieved. These effects result in improved fracturing fluid mobility within the formation pores, improved recovery of the fracturing fluids and greater production of the reservoir fluids.

More than just

completions

N2 can also benefit

Well drilling and construction:

-

Freeing differentially stuck pipe

-

Underbalanced drilling

-

Reduced cement density with foamed cementing

Completions and workovers:

-

Enhance coiled tubing operations

-

Lighten liquid columns in wellbores

Stimulation and hydraulic fracturing:

-

Commingle with acid to improve

treatment penetration -

Stimulate coal bed methane wells and low pressure reservoirs without reservoir damage

Facilities and pipeline:

-

Purge facilities and pipelines for safe turnarounds and repairs

-

Effectively pressure test facilities and pipelines

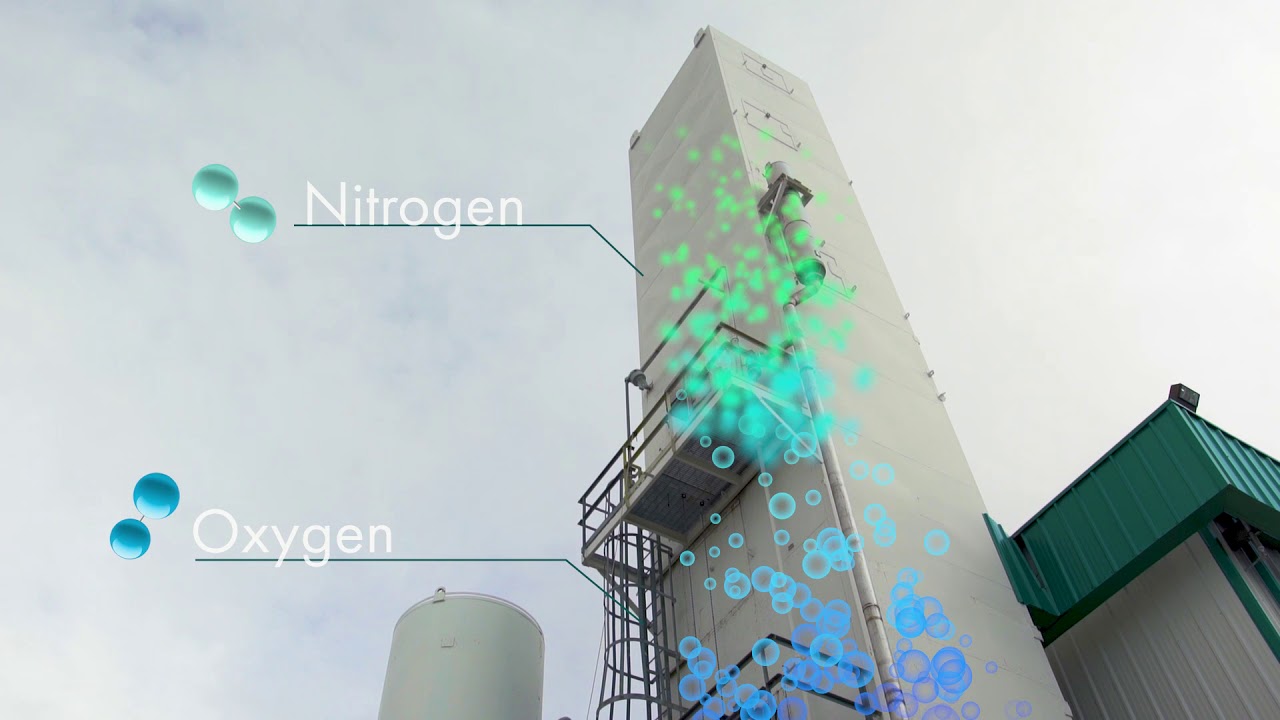

Ferus has three N2 plants located in Alberta and British Columbia ready to service operations throughout the WCSB. Our fleet and on-site services ensure seamless product delivery from plant to well site.

N2 has been used in hydraulic fracturing operations for over 50 years, and many field case studies have shown that completions conducted using these gases are less costly and well performance and economics are enhanced.

SPE 168632 and 175948

Fresh water usage may be reduced by up to 80% with the use of N2 and/or CO2 in hydraulic fracturing operations.

How we make Liquid Nitrogen